Business Process

Process Design Tips From DHL

As a process designer, I’m always looking at how other companies design their processes, in particular how they manage exceptions, errors, and unexpected actions, typically an ‘edge case.’

[Learn more about these templates here]

Last month I bought two computers. One Toshiba laptop, the second an Alienware desktop, which came in two shipments as the parts somehow came from different warehouses.

Now, you would think that companies are large as Dell and other global giants would have the delivery process nailed. After all, getting these shipments to you is the last part of the process. If you don’t get it, or if there is an error with the shipment, there’s a chance you’ll want a refund. All that effort lost.

As someone who makes a living in process design, I tend to see errors and breakdowns in procedures that maybe others don’t. Maybe they do see it but don’t label it as process design breakdown. The alarm bells don’t go off.

Here’s what happened.

I order the Alienware PC. Very expensive. As the monitor came from a different depot, it would be shipped separately. So, one order, two deliveries. You can see where this is going.

I gave them two phone numbers when completing the online order form. There’s a reason they want these numbers right? The main one is mine, the second my wife’s. All good so far.

A few weeks later we get a phone call. The order will be delivered on Friday. Friday comes and goes. No delivery.

Then an email. It will be there between Wed and Friday. Not the next Wed, but the one that’s past.

Next, we find a card in our mailbox. The delivery company had come on Tuesday but, as we were not at home, couldn’t make the delivery.

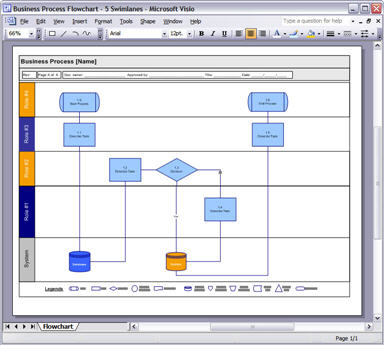

Business Process Flowchart – 4 Swim lanes

[Learn more about these Process Design Excel templates here]

But we were at home!

I was working at home that day. So was my wife. What happened was: they rang the bell, no one answered, so they left. The bell is broken; my fault. But they had two numbers, remember.

So, I called the delivery company.

Hey, what happened? We were both at home. Why didn’t you call?

Answer: he didn’t have time to call.

Sorry? He had our number, right?

Ok.

But he didn’t call? You’re kidding?

He was too busy to call. Then she added, do you want him to call back tomorrow?

Now, the delivery company’s depot is 45 minutes away. This means he brought it all the way to my house, rang the bell, left a card, drove back to the depot, and was going to come back tomorrow.

I had to say: wouldn’t it be simpler if he called? We were in the kitchen. About five seconds away.

The response?

No, our policy is to leave a card. That’s the process we follow.

Why is this happening?

- The person writing the process doesn’t work/live/drive the delivery truck.

- The person at the call center is following a procedure.

- The person driving the truck is also following a procedure.

The real problem here is that there is no mechanism to flag broken processes. Common sense would have suggested the driver stop and call us, saving him a second trip back.

The next week DHL delivered the Toshiba. They called. I wasn’t at home but asked them to leave it with a neighbour, which they did.

Sometimes, common sense is not so common.

[Learn more about these Process Design MS Word template

Editor’s Note: This post was originally published in Nov 2014 and has been updated for freshness, quality, and comprehensiveness.